Image 1 of 8

Image 1 of 8

Image 2 of 8

Image 2 of 8

Image 3 of 8

Image 3 of 8

Image 4 of 8

Image 4 of 8

Image 5 of 8

Image 5 of 8

Image 6 of 8

Image 6 of 8

Image 7 of 8

Image 7 of 8

Image 8 of 8

Image 8 of 8

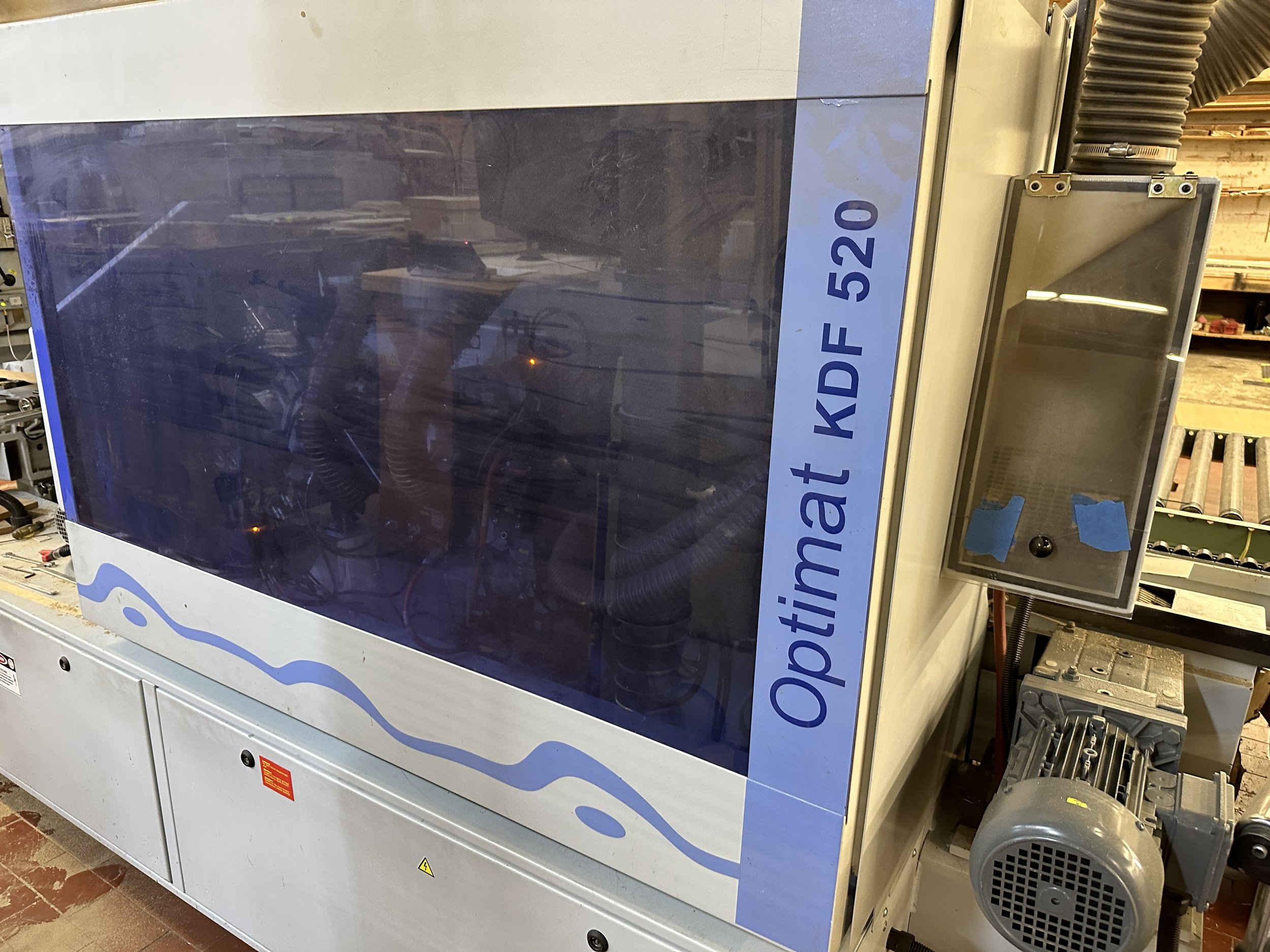

Brandt KD-77-2C Edgbander with Corner Rounding (USED, 2001)

Brandt KD-77-2C Edgbander with Corner Rounding (USED, 2001)

Model: KD-77-2C

SN: 0-250-XXXX

Year: 2001

220/440V; 60Hz; 3~

Stock#: 1206-14

Product Details

Edge cap.: 0.4 - 12mm (1/2");

Panel thickness 5/16" - 1-9/16";

Min. panel length 160 mm (6-3/8");

Min. width 65 mm (2-1/2");

Line control (NO limit switches) for workstation function.

Manual height adjustment with top pressure beam for all work station, equipped with digital height indicator.

Signal infeed light to insure proper spacing between panels.

Quick heat-up glue system, "quick change" glue tank for maintenance & glue color change; reversible rotation glue roller w/infrared heat zone to follow.

Automatic magazine for strip & coil (Large coil table 800 mm diameter to accommodate large coils of 3 mm PVC) stock, 3 mm PVC guillotine, (1) drive plus (3) idle roll "pneumatically controlled" pressure sections.

End Trim: Double motor end trim (1/3 HP - 12,000 RPM motors),

PLC controlled chamfer from 0° - 15°;

Top & Bottom flush/radius trim, 0° - 45° bevel; (1/2 HP - 12,000 RPM motor), with insert knives for 3 mm PVC radius; 2-position control through PLC.

Corner Rounding: 2-Motor corner rounding unit for top & bottom corners (0.5 HP - 12,000 RPM motors)

Profile Scraping: top & bottom scraping for 2 - 6 mm radius, pneumatically controlled blowoff nozzles.

Buffing: top & bottom buffing (0.25 HP - 1,400 RPM motors).

End trim & flush trim stations have HF motors w/electronic brakes; feed chain track speed 42 FPM, 2 HP feed drive. Pneumatic Exclusion/Inclusion on all major stations.

Complete with: Operator control panel w/PLC (Programmable Logic Control) keypad & LED readouts, and used tooling.

Ask about a return conveyor for this machine.

Brandt KD-77-2C Edgbander with Corner Rounding (USED, 2001)

Model: KD-77-2C

SN: 0-250-XXXX

Year: 2001

220/440V; 60Hz; 3~

Stock#: 1206-14

Product Details

Edge cap.: 0.4 - 12mm (1/2");

Panel thickness 5/16" - 1-9/16";

Min. panel length 160 mm (6-3/8");

Min. width 65 mm (2-1/2");

Line control (NO limit switches) for workstation function.

Manual height adjustment with top pressure beam for all work station, equipped with digital height indicator.

Signal infeed light to insure proper spacing between panels.

Quick heat-up glue system, "quick change" glue tank for maintenance & glue color change; reversible rotation glue roller w/infrared heat zone to follow.

Automatic magazine for strip & coil (Large coil table 800 mm diameter to accommodate large coils of 3 mm PVC) stock, 3 mm PVC guillotine, (1) drive plus (3) idle roll "pneumatically controlled" pressure sections.

End Trim: Double motor end trim (1/3 HP - 12,000 RPM motors),

PLC controlled chamfer from 0° - 15°;

Top & Bottom flush/radius trim, 0° - 45° bevel; (1/2 HP - 12,000 RPM motor), with insert knives for 3 mm PVC radius; 2-position control through PLC.

Corner Rounding: 2-Motor corner rounding unit for top & bottom corners (0.5 HP - 12,000 RPM motors)

Profile Scraping: top & bottom scraping for 2 - 6 mm radius, pneumatically controlled blowoff nozzles.

Buffing: top & bottom buffing (0.25 HP - 1,400 RPM motors).

End trim & flush trim stations have HF motors w/electronic brakes; feed chain track speed 42 FPM, 2 HP feed drive. Pneumatic Exclusion/Inclusion on all major stations.

Complete with: Operator control panel w/PLC (Programmable Logic Control) keypad & LED readouts, and used tooling.

Ask about a return conveyor for this machine.

*This machine is offered in good running condition as taken from service and is subject to prior sale. Specifications are approximate and to the best of our knowledge. Verification is available upon request.